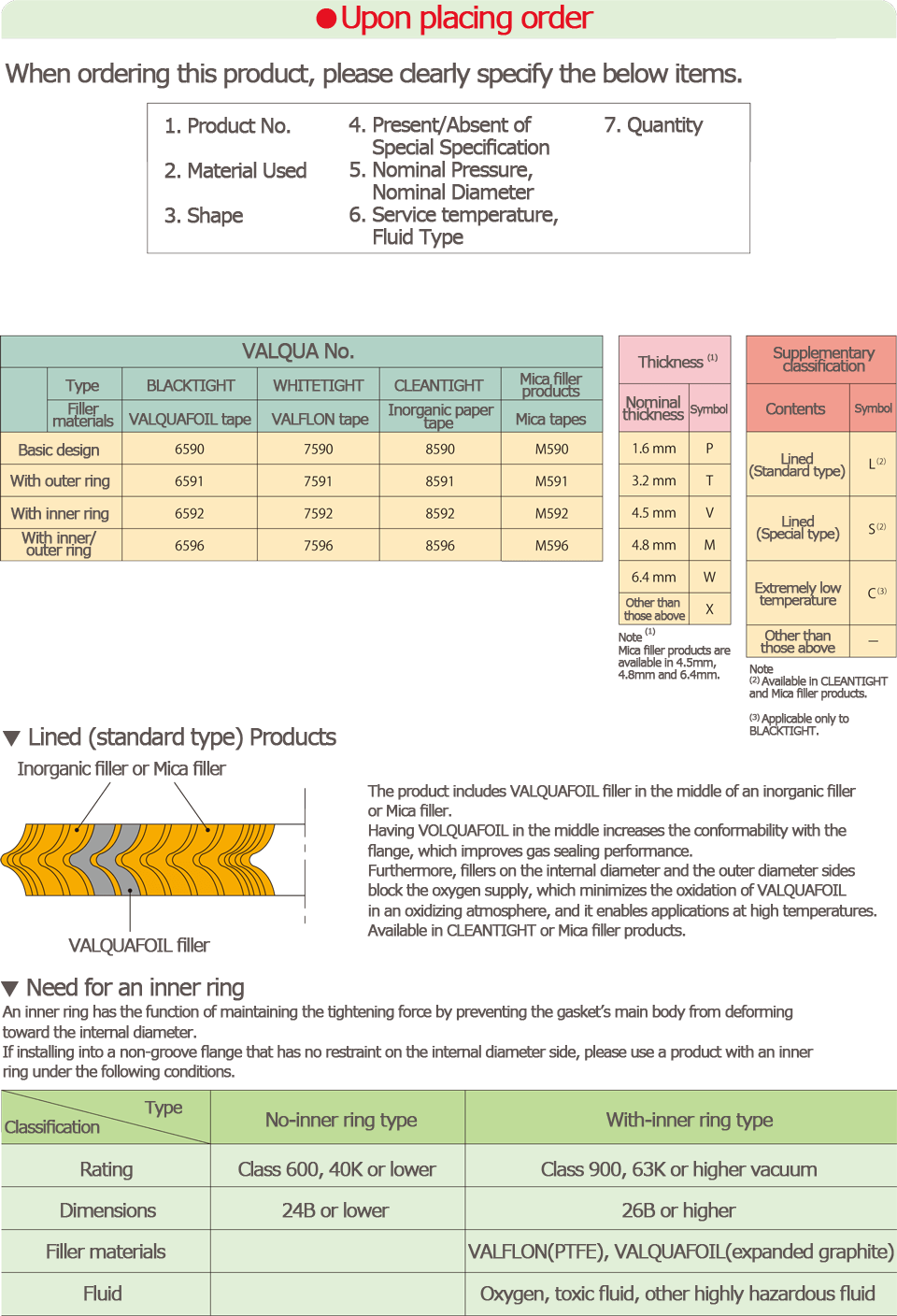

Spiral Wound Gaskets use Non-Asbestos inorganic paper, VALQUAFOIL™ (expanded graphite) and VALFLON™ (PTFE) tape as filler materials, and exhibit good elasticity by means of a V-shaped hoop.

|

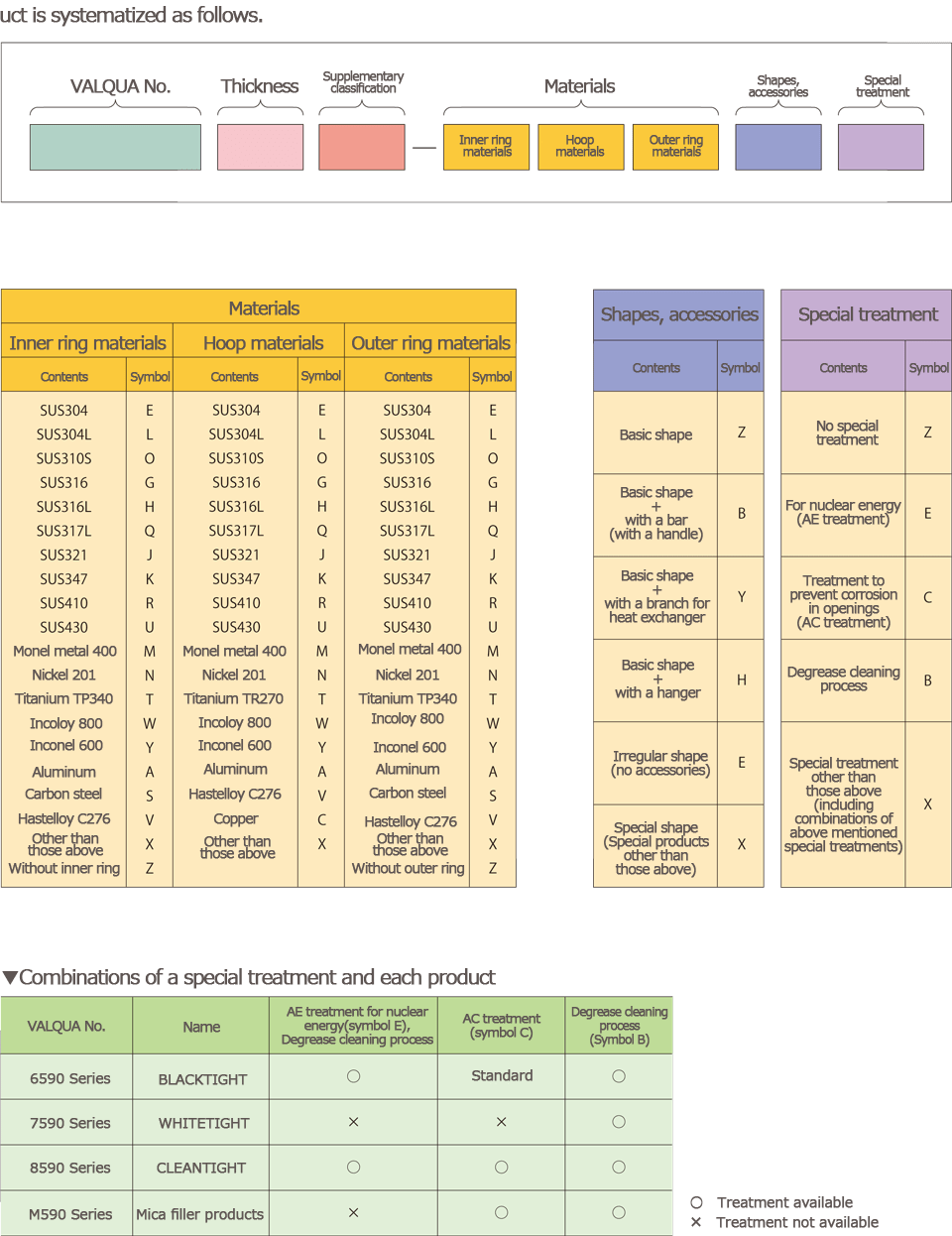

Applicable fluids |

Water, Sea water, Hot water, Steam,Crude oil, Alcohol, Animal & vegetable oil, Heat transfer oil,General solvent, Weak acid, Weak alkali,Strong oxidizing acid, strong alkali,Air, Nitrogen gas, Inert gas,Exhaust gas,Inflammable gas,Poisonous,Extremely low temperature liquids, |

|

Inappropriate fluid |

Oxidizing acids such as hot, concentrated sulfuric acid, concentrated nitric acid and oxygen. |

|

Application |

In particular best suited as gaskets for use handling high temperature & high pressure steam (except HTS), as well as very low temperature fluids such as LNG, liquid nitrogen and liquid hydrogen. |

Standard Flange: For JIS pipe flanges=10K、16K、20K、30K、40K、63K For JPI and ANSI pipe flanges=Classes 150, 300, 400, 600, 900, 1500, 2500 Gaskets complying with other standards such as ASME and MSS are also available.

Non-Standard Flange

| Gasket thickness(mm) | Manufacturing ranges |

| 1.6(P) | 10〜150 |

| 3.2(T) | 10〜1500 |

| 4.5(V) | 10〜3000 |

| 6.4(W) | 300〜3400 |

Products with a gasket thickness of 6.4 mm can be fabricated with the outer diameter of the outer ring of up to 3,500. In case of products with gasket thickness of 1.6 mm, only the basic type with hoop made of SUS316 are available. "( )" shows thickness classifications.

Round type gaskets are available.

| Basic design | With outer ring | With inner ring | With inner/outer ring |

|

|

|

|

Filler material: VALQUAFOIL tape

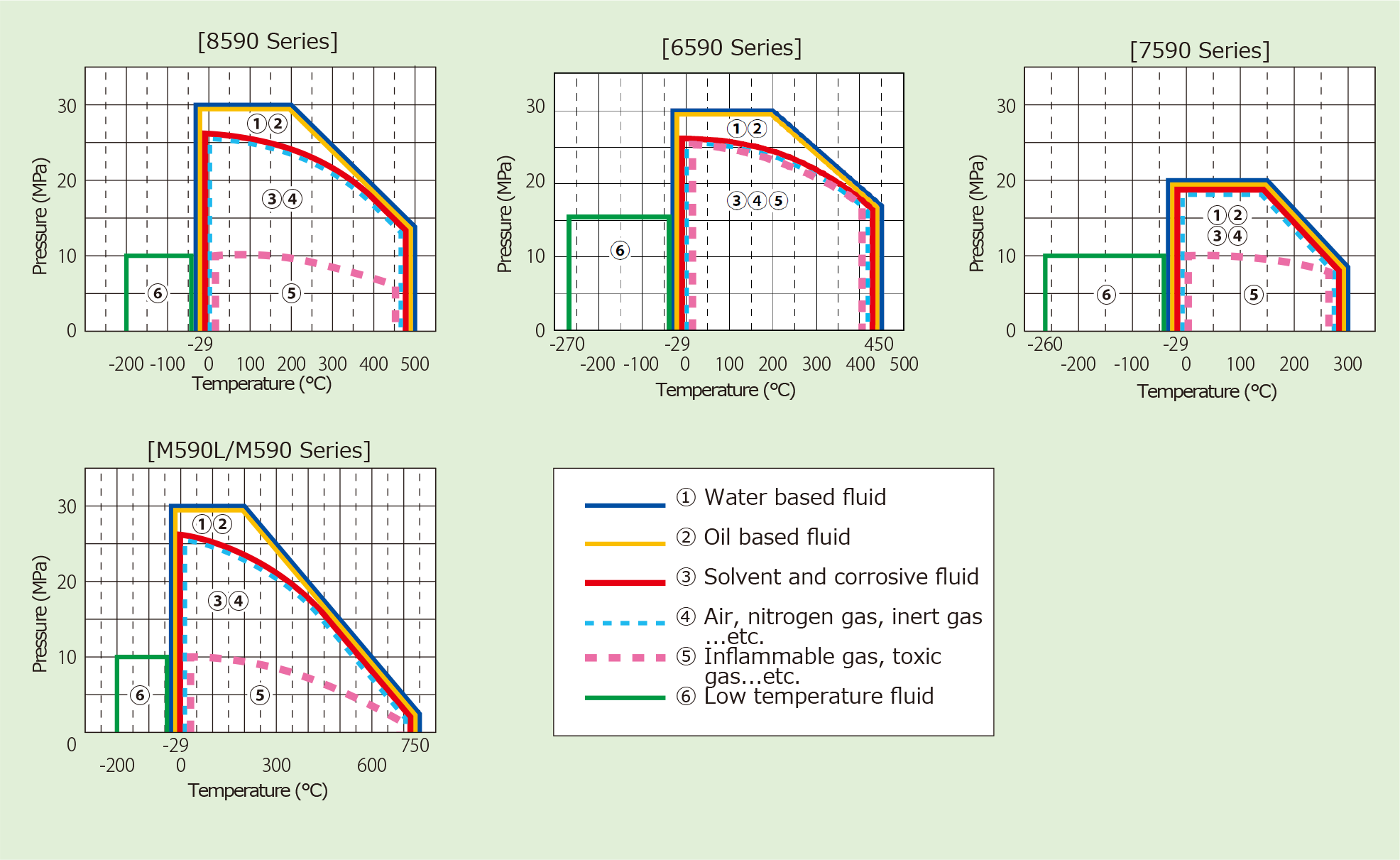

| Temperature(℃) | Pressure(MPa) |

| -270〜450 | 30.0 |

1. Temperature and pressure show individual service limits.

2. The above temperature ranges vary depending on the material used for the hoops and the inner & outer rings.

| Gasket factor”m” | Minimum design seating stress"y" (N/mm2) |

Recommended tightening stress (MPa)Liquid |

Recommended tightening stress (MPa)Gas |

| 3.0 | 68.9 | 35.0 | 50.0 |